Automation & AI Analytics

Flexdata (v.2.1)

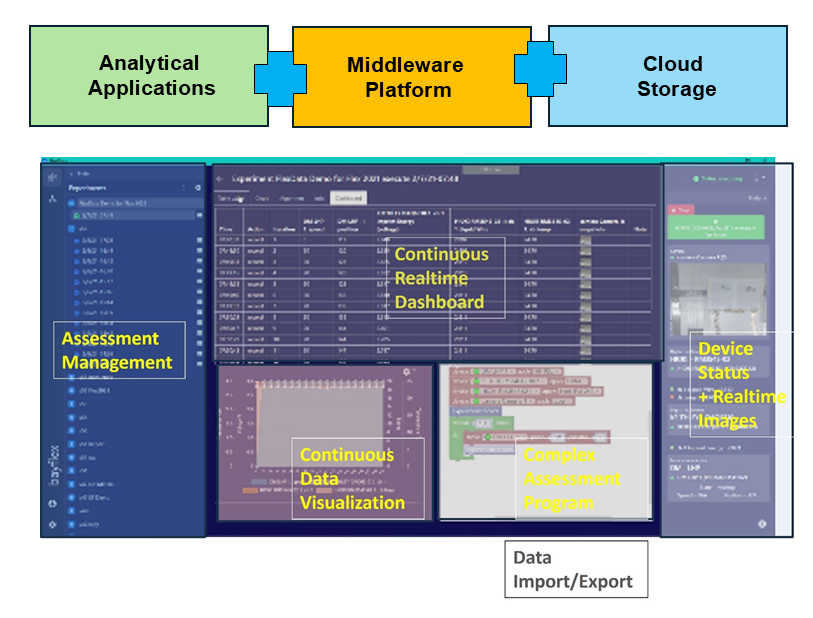

An intuitive, plug-and-play data analytics platform that controls devices and acts as a bridge between raw data from testing devices and AI-powered insights. A user-friendly, non-programming solution to simplify data management. The platform provides real-time data aggregation, automated reporting, and remote monitoring to accelerate the development of simulation models for flexible electronics.

-

Can work with: P150, C*BR, TW, FT, CS, FS/FS-C, FS-N, FU, 4U, FR, PP, ST

PC Specifications

OS (Required): Windows 10/11

OS (Recommended): Windows 10/11 (32bit/64bit)

Resolution (Required): 1366 × 768

Resolution (Recommended): 1920 × 1080

CPU Clock Rate: 1 GHz or more

Memory (Required): 512 MB or more

Memory (Recommended): 8 GB or more

Free Space: 30 MB or more

Communications: USB 3.0

RJ-45 ≥ GBE

Internet ≥ 25 Mbps

Flexdata.Bobbi (Knowledge Module)

Serves as a secure custom client central repository for authorized standards, best practices, testing documentation, and system command and control information. It integrates an AI assistant, similar to a large language model like OpenAI/ChatGPT, to provide step-by-step guidance and user curated private resources. The module also focuses on creating a customizable material database for evaluating application-specific components and their performance.

Contact us for technical specs

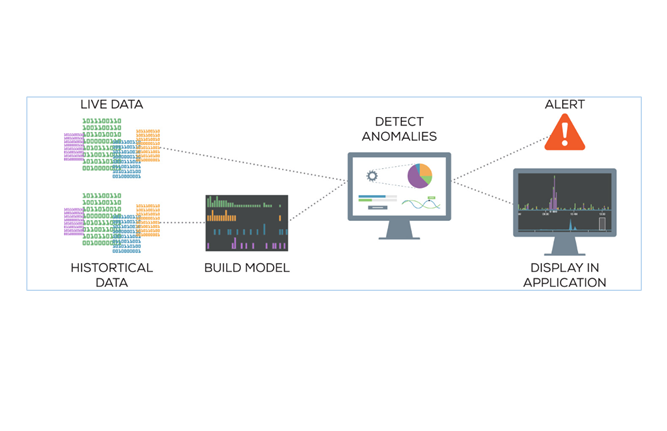

Flexdata.Leonardo (Predictive Module)

The Anomaly Detection Module (leonardo) is a component of Flexdata.ai designed to detect and monitor anomalies in electronics over time. It analyzes sensor readings and environmental factors to find early signs of material or component degradation, such as adhesive deformation or substrate delamination. With additional optical imaging, the module uses computer vision and AI agent methods to process images, identify features, and interpret data to predict potential failures.

Contact us for technical specs

+Automation

Datadump

Flexdata automatically records and backups connected data meters, sensors and cameras. For additional flexibility, this utility enables data to be extracted from the entire Flexdata platform for additional data processing.

ConnectBox

ConnectBox enables to connect on/off an external third party device and control via the Flexdata platform. We've seen some creative uses of this function, including solar swing arm (simulates sun movements), other mechanical testers and inspection tools.

How to perform continuous data measurements using Flexdata 2.1

Tutorials

How to use Connectbox with Flexdata 2.1

How to perform 40 channel data measurements using Flexdata 2.1

How to export and import Flexdata algorithms

How to perform action replay and SmartStop using Flexdata 2.1